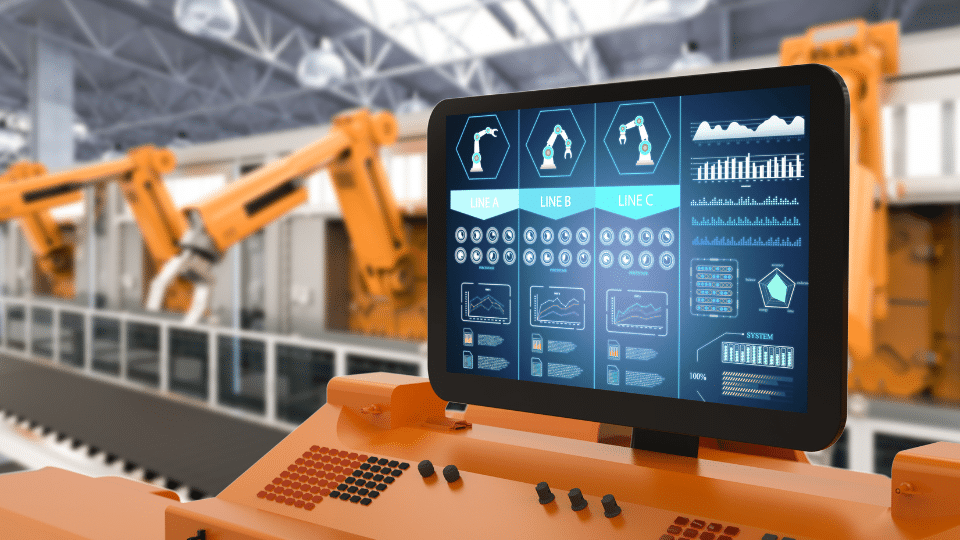

The FOCUS Advanced Manufacturing team recently returned from our trip to the International Manufacturing Technology Show in Chicago. Our main takeaway from the gathering can probably be summed up in one word—Automation.

When you think of automation, you usually think of large manufacturing plants, like an automobile assembly plant, with hundreds of robotic arms installing doors and other parts and spot-welding thousands of connections. Indeed, the auto industry largely pioneered the use of automation in the context of early assembly lines, back when Henry Ford was building the Model T. And traditionally, automation has only been done by large manufacturers because it’s so expensive but becomes economically feasible when churning out lots of identical, finished products.

Now, however, automation is coming to the advanced machine shop. Modern machines already use a great deal of robotic automation – within the esoteric boundaries of the operating envelope of the machine, but there’s much room to go in terms of machine loading, materials handling, etc. But the same principle of automating high-volume work at an auto assembly plant has now come to low-volume, high-mix metalworking job shops and contract manufacturers that make parts and assemblies for customers in multiple industries. Shop owners better be prepared to embrace it—for at least part of the manufacturing process—if they expect to stay in business.

Now, don’t panic. The cost of automation has come down to where it is within the means of even the small- to medium-sized shop. You don’t have to be General Motors to make it happen. Nor do you have to automate your entire shop. But there are aspects of your manufacturing process—mainly the repetitive, dull, and dirty jobs—that probably could be automated, while leaving the customized and most complicated parts of your process in the hands of your skilled machinists.

The Wall Street Journal recently reported that Walgreens “is turning to robots to ease workloads at drugstores as it grapples with a nationwide shortage of pharmacists and pharmacist technicians.” Sound familiar? But it’s not just giant pharmacies like Walgreens that are trying to automate some of their procedures. “More drugstores, including smaller chains and independent pharmacies, are looking to automate and centralize drug fulfillment,” the article said. The same principal holds true in the metalworking industry.

At IMTS we saw machines that automate the inspection of parts as they’re being made, quality control solutions, even production environments that can fully manufacture parts with a minimum need for human involvement. And just about every piece of equipment on display was digitally enabled.

Actually, we probably need to revise our takeaway to two words—Flexible Automation. Flexible automation means you can program a robot or other automated process to fit whatever the particular project you’re working on at that moment. It’s not just for massive production lines. The technology has advanced to the point where it can be programmed by one of your own machinists to do multiple jobs as your needs and orders change, without having to hire a programmer to tell it what to do.

Benefits of automation

The move toward more automation has many benefits.

Cost savings from automation can be significant. When owners want to sell their businesses, they want the highest valuation possible. One way to increase that value is by increasing your profit margins. A newly automated, highly efficient shop is not only more likely to be more profitable, but also more likely to take on more new business, adding even more value through revenue growth and potentially additional margin expansion. The savings quickly multiply with the job size.

Tied in with that is the increase in quality, which also drives margins. The most demanding customers in industries like aerospace accept nothing less than perfection, something that only automation can provide.

Ask any manufacturing professional what their top pain point is and the resounding answer is almost always finding skilled workers. Automation can be part of the solution, by freeing up your skilled machinists to do the more complex tasks while leaving the repetitive dull jobs to the robots. With the right products and processes selected for automation, you may be able to take on more work without adding more employees.

By the same token, the machine shop of the not-too-distant future may be hiring more computer programmers and IT people to manage these processes. Right now, IT and computer science graduates largely eschew manufacturers in favor of jobs in the high-tech industry. The automated machine shop may be a more attractive landing spot for them going forward.

Competition may give you no choice but to automate—it becomes a matter of survival. Smaller companies need to automate to remain competitive with bigger companies that are already automating. If you can’t handle that big order, someone else can.

While automation won’t solve every challenge, it’s increasingly hard to ignore. Every shop should be looking at one or two of their processes that are inefficient, then do a cost benefit analysis to see what aspects can or should be automated.

You don’t need to figure it all out at the beginning, but it’s a good idea to at least get started. Find a simple task that can readily benefit from automation. Start small with maybe a couple of operations, and then expand it out to something more complex. Sometimes the solution requires a rethinking of the process, perhaps redesigning the process to support an automated approach versus the former human-driven approach.

Apply the 80/20 rule. If 20% of what you do is relatively simple or repetitive and can be easily automated, focus there first and free up some skilled and experienced machinists for tougher, more complex (and higher margin) work. They’ll appreciate the opportunity to step up their personal game and your bottom line will benefit from the improved margins and the higher revenue automation makes possible.